Zogulitsa

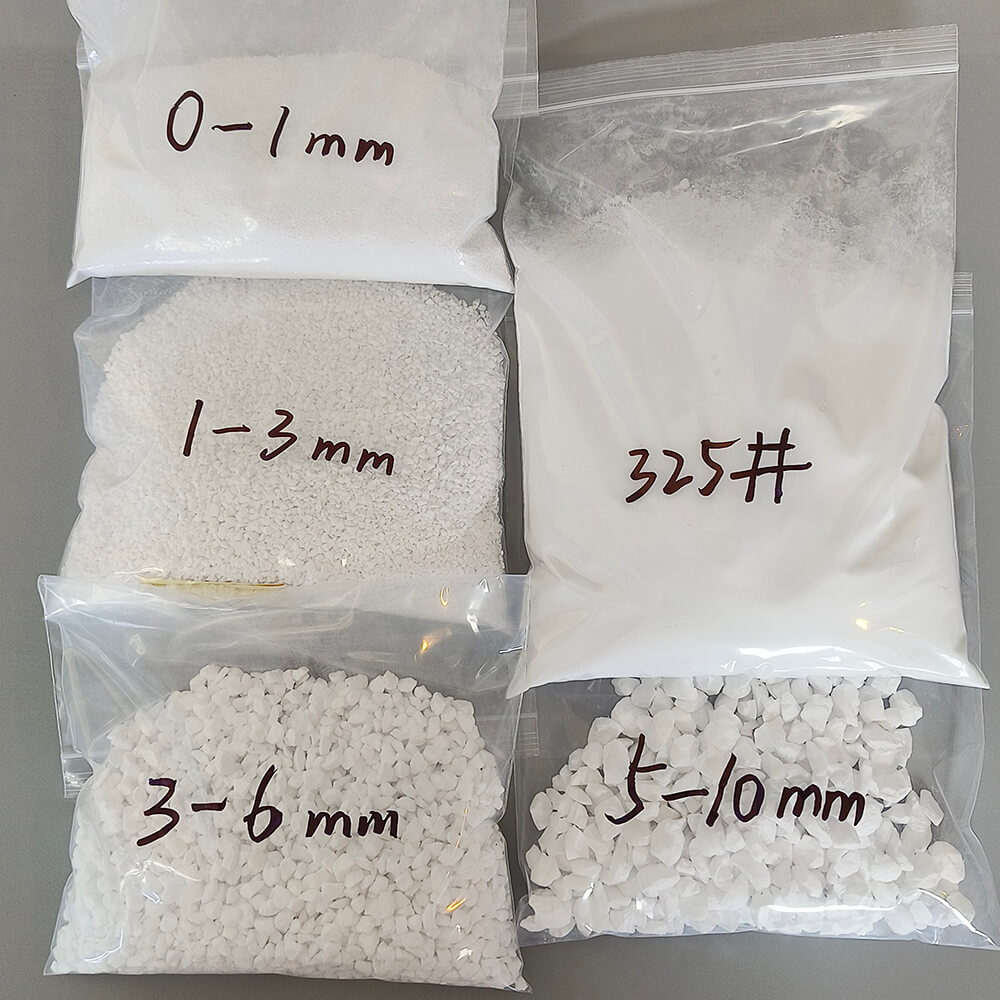

Tabular Alumina for Refractory Dry Ramming Mass Sintered Tabular Alumina for Refractory Raw Materials

Sintered Tabular Alumina Kufotokozera

Tabular corundum, amadziwikanso kutisintered tabular alumina, ndi mawonekedwe apamwamba a alumina (Al2O3) omwe amakonzedwa kuti akhale ndi amawonekedwe apadera a tabular, kapena athyathyathya. Zimapangidwa ndi sintering (kutentha popanda kusungunuka) ufa wapamwamba wa alumina pa kutentha pamwamba pa 1900 ° C, zomwe zimapangitsa kuti particles za alumina zikule ndikupanga makristasi akuluakulu, ophwanyika, ngati mbale.

Kufotokozera kwa Tabular Corundum

| Tabular corundum Kufotokozera | ||

| Kanthu | Standard | Yesani |

| Mphamvu yokoka | 3.5g/cm3 min | 3.56g/cm3 |

| Kuwoneka kwa Porosity | 5.0% kupitirira | 3.5% |

| Kumwa Madzi | 1.5% max | 1.1% |

| Chemical Composition | ||

| Kanthu | % | Yesani % |

| Al2O3 | 99.2 mphindi | 99.4% |

| Na2O | 0.40 max | 0.29% |

| Fe2O3 | 0.10 max | 0.02% |

| CaO | 0.10 max | 0.02% |

| SiO2 | 0.15 max | 0.03% |

| Kugwiritsa ntchito: Tabular corundum imagwiritsidwa ntchito kwambiri pazinthu zotsutsa kwambiri m'magawo azitsulo, kuponyera, petrochemicals, njerwa mpweya, ladle linings, castables, prefabricated mbali, zoumba ndi zina.. Ndibwino kwambiri kupanga refractory yaiwisi. Tabular corundum imagwiritsidwa ntchito ngatiRefractory aggregateangagwiritsidwe ntchito osakaniza spinel, calcined adamulowetsa aluminiyamu ndi zomangira monga simenti, dongo kapena utomoni. Njerwa zokonzedwa bwino za corundum zimakhala ndi zonyansa zochepa (monga SiO2), kachulukidwe kakang'ono kwambiri komanso katundu wabwino wa thermodynamic, kupanga njerwa za corundum Njerwa zimagonjetsedwa ndi kutentha, mankhwala ndi kuwonongeka kwapangidwe chifukwa cha ntchito ya gasifiers ndi ng'anjo zina za mafakitale. | ||

| Ubwino wake:mkulu refractoriness; kukana dzimbiri; kukana kukokoloka kwakukulu; mkulu matenthedwe kukana mantha; kulimba kwakukulu, kulimba kwabwino; khola mankhwala katundu; kukana kukokoloka kwa slag zamchere, kukana kukokoloka kwa slag, komanso kukana kukokoloka kwachitsulo chosungunuka; Kugonjetsedwa ndi kukokoloka ndi chitsulo chosungunuka komanso mpweya wabwino wodutsa. | ||

Kugwiritsa ntchito tabular corundum

- Zotsutsa

- Foundry ndi Investment Casting

- Kupanga Ma Ceramics

- Abrasives ndi kupukuta

- Zothandizira za Catalyst

- Zida za Insulation

- Makampani a Electronics ndi Semiconductor

Kufufuza Kwanu

Ngati muli ndi mafunso.Chonde khalani omasuka kulankhula nafe.

fomu yofunsira

Lembani uthenga wanu apa ndikutumiza kwa ife