Zogulitsa

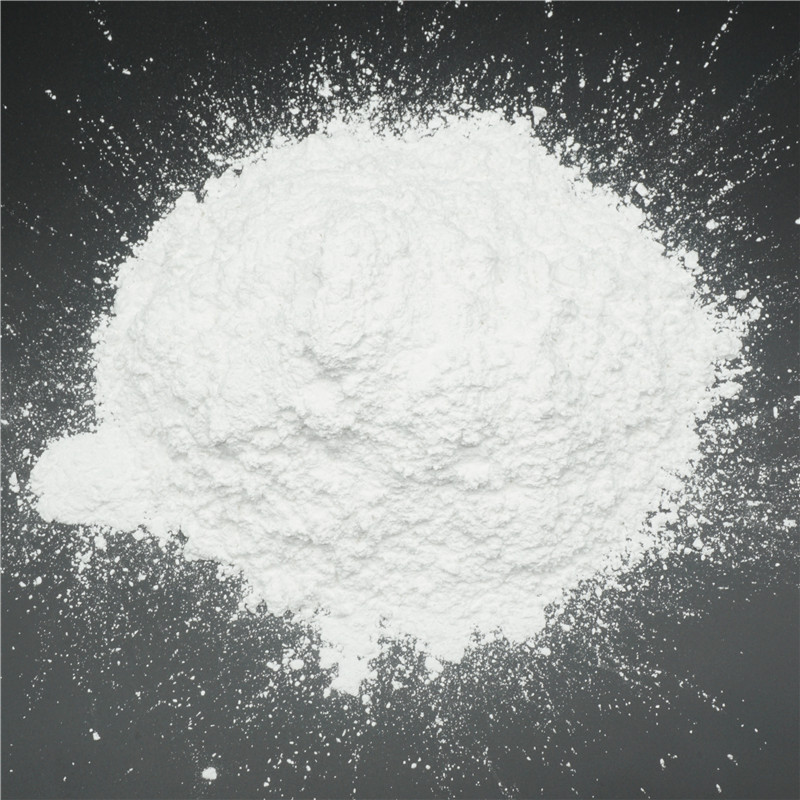

Platelet Calcined Alumina Powder

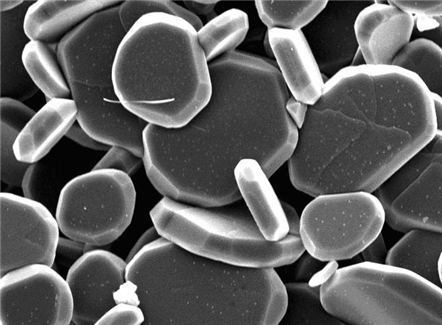

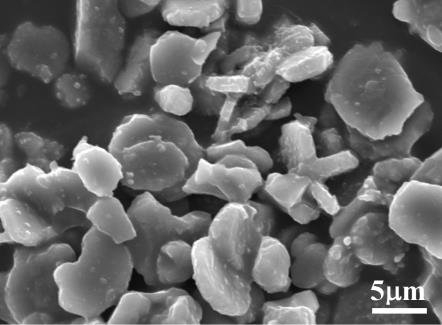

Plate Calcined Alumina kupukuta ufa amapangidwa ndi apamwamba aluminiyamu mafakitale ufa monga zopangira, ndi kukonzedwa ndi njira yapadera kupanga.Maonekedwe a kristalo a ufa wopangidwa ndi alumina wopukuta ndi hexagonal lathyathyathya ngati mawonekedwe a tabular, motero amatchedwa Platelet Alumina kapena Tabular Alumina.

Platelet Alumina ndi mtundu wapamwamba kwambiri wa alumina wa ufa wonyezimira, wopangidwa ndi kristalo wooneka ngati mbale wa Al2O3 wokhala ndi chiyero choposa 99.0%.Ili ndi zinthu zabwino kwambiri zolimbana ndi kutentha komanso kusagwira ntchito ndi mankhwala, ndipo sikuwonongeka ndi ma acid kapena alkaline.Pamene tinthu tating'ono kukula kwa Platelet Alumina imayendetsedwa mwamphamvu, imatha kutulutsa malo abwino kwambiri, ndikupangitsa kuti ikhale yogwira mtima kwambiri ngati chotupa.Ndi zinthu zambiri zomwe zimagwiritsidwa ntchito, Platelet Alumina ndi ufa wonyezimira womwe ungathe kugwira ntchito zambirimbiri.

Tabular alumina ufa

Tabular alumina ufa

Zokhazikika Zokhazikika Pakukula kwa Tinthu

| Tinthu | Kugawa Tinthu (µm) | |||

| Maximum tinthu | Tinthu kukula | Tinthu kukula | Tinthu kukula | |

| 45 | <82.9 | 53.4± 3.2 | 34.9± 2.3 | 22.8± 1.8 |

| 40 | <77.8 | 41.8± 2.8 | 29.7± 2.0 | 19.0± 1.0 |

| 35 | <64.0 | 37.6± 2.2 | 25.5± 1.7 | 16.0± 1.0 |

| 30 | <50.8 | 30.2± 2.1 | 20.8± 1.5 | 14.5± 1.1 |

| 25 | <40.3 | 26.3± 1.9 | 17.4 ± 1.3 | 10.4± 0.8 |

| 20 | <32.0 | 22.5± 1.6 | 14.2± 1.1 | 9.00±0.80 |

| 15 | <25.4 | 16.0± 1.2 | 10.2± 0.8 | 6.30±0.50 |

| 12 | <20.2 | 12.8± 1.0 | 8.20±0.60 | 4.90±0.40 |

| 9 | <16.0 | 9.70±0.80 | 6.40±0.50 | 3.60±0.30 |

| 5 | <12.7 | 7.20±0.60 | 4.70±0.40 | 2.80±0.25 |

| 3 | <10.1 | 5.20±0.40 | 3.10±0.30 | 1.80±0.30 |

Quality Standard

| Mtundu wa mankhwala | Specific Gravity | ||||

| Al2O3 | SiO2 | Fe2O3 | Na2O | ||

| 3µm-45µm | 3.90 | >99.0 | <0.20 | <0.10 | <1.00

|

Ubwino wa Alumina Powder

1. Yerekezerani ndi ufa wina wa tabular, ufa wa aluminiyamu wa tabular uli ndi zosakaniza zabwino kwambiri.Monga malo osungunuka kwambiri, kuuma kwamphamvu, mphamvu zamakina apamwamba, kukana kwabwino, kukana mankhwala, kukana kwa okosijeni ndi kukana kutentha etc.

2. Mawonekedwe a pepala lathyathyathya amapangitsa kukangana kwakukulu, kumapangitsa kuti mphesa ikhale yofulumira komanso yogwira ntchito bwino, izi zingachepetse chiwerengero cha makina opera, ntchito ndi nthawi yopera.

3. Maonekedwe a pepala lathyathyathya amapangitsa kuti chinthucho chikhale chosavuta kukanda, mlingo wa mankhwala oyenerera ukhoza kuwonjezeka 10% -15%.Mwachitsanzo, mlingo wa oyenerera semiconductor pakachitsulo chopingasa angafikire 96% kapena kuposa.

4. Ali ndi zotsatira ziwiri za nano ndi ufa waung'ono, ntchito ya pamwamba ndi yochepetsetsa, osati yogwirizana bwino ndi magulu ena ogwira ntchito, komanso zovuta kugwirizanitsa ndikuthandizira kubalalitsidwa kothandiza.

5. Ali ndi zomatira bwino, zoteteza kwambiri komanso amatha kuwonetsa kuwala.

6. Tabular alumina ufa umakhala woonekera bwino, wopanda mtundu, ndipo uli ndi malo osalala komanso osalala.Makhiristo owoneka bwino ndi ma hexagon okhazikika.

7. Tabular alumina ufa ukhoza kupangidwa kukhala ufa wonyezimira wabwino kwambiri.

1. Makampani opanga zamagetsi: kugaya ndi kupukuta kwa semiconductor monocrystalline silicon wafers, quartz quartz crystals, semiconductors apawiri (crystalline gallium, phosphating nano).

2. Makampani agalasi: kugaya ndi kukonza kristalo, galasi la quartz, chipolopolo cha galasi la kinescope, galasi la kuwala, galasi lamadzimadzi (LCD) galasi la galasi, ndi galasi la quartz.

3. Makampani okutira: zokutira zapadera ndi zodzaza kupopera mbewu kwa plasma.

4. Zitsulo ndi ceramic processing makampani: mwatsatanetsatane ceramic zipangizo, sintered ceramic zopangira, apamwamba kalasi zokutira mkulu-kutentha, etc.

Kufufuza Kwanu

Ngati muli ndi mafunso.Chonde khalani omasuka kulankhula nafe.