Zogulitsa

Metal abrasive Steel Grit Blast Media

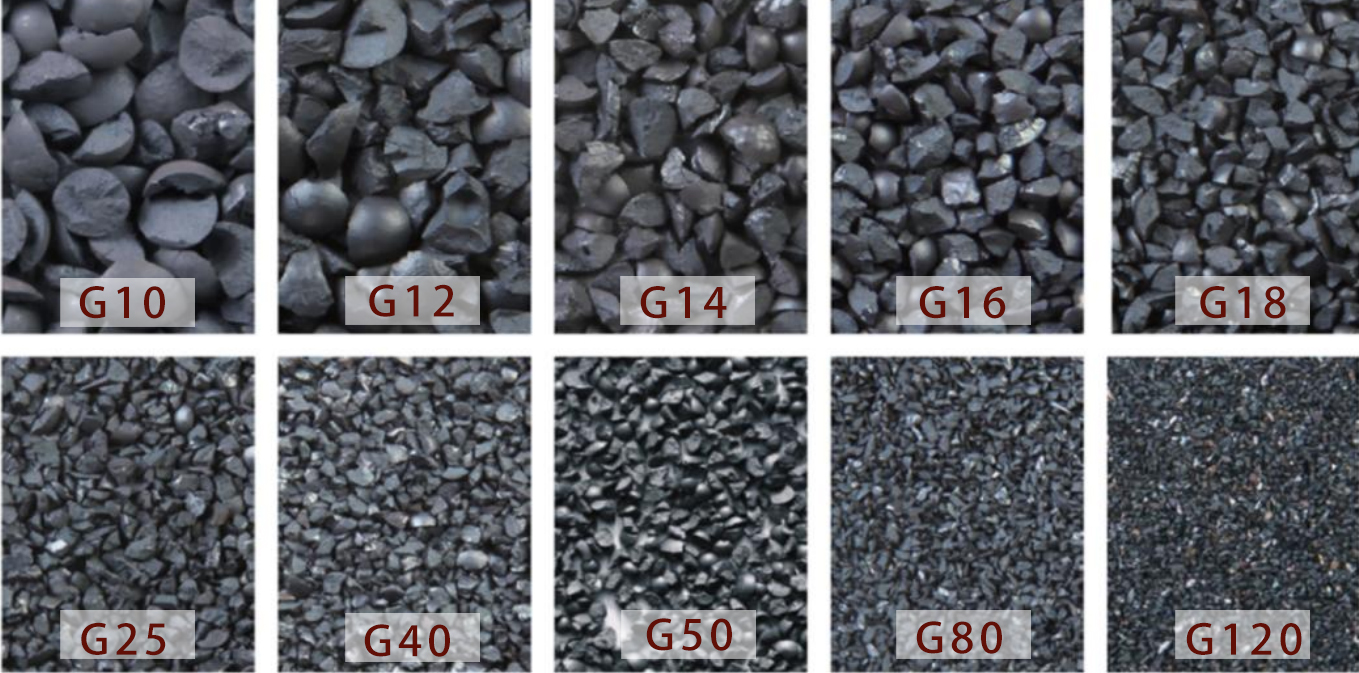

CHIZINDIKIRO GRIT

Makanema ankhanzawa amagwiritsidwa ntchito pophulitsa ndi kuvula zitsulo ndi zitsulo zoyambira. Steel Grit imapanga bwino zomangira pazitsulo zolimba kuti zimamatire bwino zokutira kuphatikiza utoto, epoxy, enamel ndi mphira. Zomwe zimagwiritsidwa ntchito zimaphatikizapo kukonza magalimoto a njanji, kuchotsa zowunikira, milatho yophulitsa, zida zachitsulo ndi ntchito zamafakitale.

| Zogulitsa | Grit yachitsulo | |

| Chemical Composition | CR | 1.0-1.5% |

| C | 1.0-1.5% | |

| Si | 0.4-1.2% | |

| Mn | 0.6-1.2% | |

| S | ≤0.05% | |

| P | ≤0.05% | |

| Kuuma | Kuwombera kwachitsulo | GP 41-50HRC;GL 50-55HRC;GH 63-68HRC |

| Kuchulukana | Kuwombera kwachitsulo | 7.6g/cm3 |

| Micro kapangidwe | Martensite kapangidwe | |

| Maonekedwe | Tinthu tating'onoting'ono tozungulira <5% Mng'alu wa tinthu <3% | |

| Mtundu | G120,G80,G50,G40,G25,G18,G16,G14,G12,G10 | |

| Diameter | 0.2mm, 0.3mm,0.5mm,0.7mm,1.0mm,1.2mm,1.4mm,1.6mm,2.0mm,2.5mm | |

Ntchito ya Steel Grit

1.Kukonzekera Pamwamba: Zitsulo zachitsulo zimagwiritsidwa ntchito kwambiri pokonzekera pamwamba musanagwiritse ntchito zokutira, utoto, kapena zomatira. Amachotsa bwino dzimbiri, sikelo, zokutira zakale, ndi zonyansa kuchokera pazitsulo zachitsulo, kuonetsetsa kumamatira koyenera kwa zinthu zotsatila.

2.Kuchotsa Dzimbiri ndi Kuwonongeka: Zitsulo zachitsulo zimagwiritsidwa ntchito kuchotsa dzimbiri zolemera, zowonongeka, ndi mphero kuchokera kuzitsulo zazitsulo, makamaka m'mafakitale monga kumanga zombo, kukonza m'madzi, ndi kupanga zitsulo.

3.Kukonzekera Kuwotcherera: Asanayambe kuwotcherera kapena njira zina zophatikizira, zitsulo zazitsulo zingagwiritsidwe ntchito kuyeretsa ndi kukonza malo, kuonetsetsa kuti zowotcherera zamphamvu ndi zoyera.

4.Concrete ndi Stone Surface Kukonzekera: Zitsulo zazitsulo zingagwiritsidwe ntchito kuyeretsa ndi kukonza konkire ndi miyala ya miyala, monga mapulojekiti obwezeretsa, kumene kuchotsedwa kwa zokutira zakale, zowonongeka, kapena zowonongeka ndizofunikira.

5.Shot Peening: Ngakhale kuwombera kwachitsulo kumagwiritsidwa ntchito kwambiri poyang'ana, zitsulo zachitsulo zitha kugwiritsidwanso ntchito pochita izi. Kuyang'ana kumaphatikizapo kuphulitsa pamwamba ndi tinthu ting'onoting'ono tomwe timayambitsa kupsinjika, komwe kumapangitsa kuti chinthucho chikhale champhamvu komanso kuti chisatope.

6.Deburring ndi Deflashing: Zitsulo zachitsulo zimagwiritsidwa ntchito kuchotsa burrs, m'mphepete lakuthwa, ndi zinthu zowonjezera kuchokera kuzitsulo zazitsulo, makamaka popanga njira zomwe zimafunikira kulondola ndi kusalala.

7. Foundry Application: Zitsulo zachitsulo zimagwiritsidwa ntchito poyeretsa ndi kukonza malo oponyera, nkhungu ndi kuchotsa pakati, ndi chithandizo chazitsulo zonse. 8.Surface Profile: Zitsulo zachitsulo zimagwiritsidwa ntchito popanga mbiri yeniyeni, makamaka m'mafakitale monga zomangamanga ndi zomanga zombo. Ma profaili awa amathandizira kumamatira kumamatira komanso kumathandizira kuti pakhale malo oletsa kuterera.

9.Kudula Mwala ndi Kuyika: M'mafakitale omanga ndi zipilala, zitsulo zachitsulo zimagwiritsidwa ntchito podula ndi kuyika miyala ndi zipangizo zina zolimba, kupanga mapangidwe ovuta ndi mapangidwe.

10.Mafakitale a Mafuta ndi Gasi: Zitsulo zachitsulo zimagwiritsidwa ntchito pokonzekera pamwamba pamakampani amafuta ndi gasi, monga kuyeretsa mapaipi, akasinja, ndi zida zina.

11.Makampani Oyendetsa Magalimoto: Zitsulo zachitsulo zitha kugwiritsidwa ntchito kuvula utoto ndi zokutira kuchokera ku zida zamagalimoto, kukonza malo oyeretsera kapena kukonzanso.

Ndikofunika kuzindikira kuti kusankha kukula kwachitsulo choyenera, kuuma, ndi zina zimatengera ntchito yeniyeni ndi kutsiriza komwe kumafunidwa. Zowonongeka zazitsulo zazitsulo zimawapangitsa kukhala zida zamtengo wapatali pa ntchito zomwe zimafuna kuchotsedwa mwamphamvu ndi kusinthidwa pamwamba.

Kufufuza Kwanu

Ngati muli ndi mafunso.Chonde khalani omasuka kulankhula nafe.